In a world increasingly aware of environmental sustainability and energy efficiency, one of the most exciting frontiers of research lies in the utilization of waste heat. From our own bodies to the extensive machinery underpinning industry, heat is constantly produced, much of which escapes into the atmosphere without being put to use. Recent advancements have presented us with potential solutions to this issue, transforming what was once seen as waste into valuable energy.

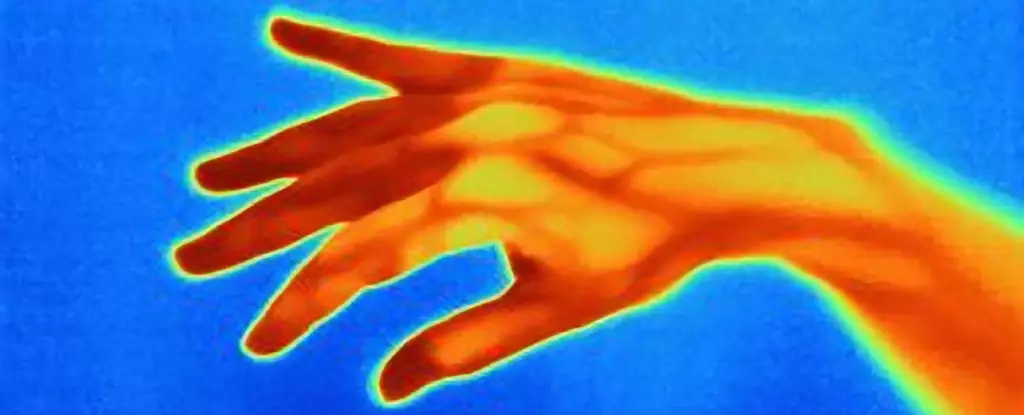

A striking realization occurs when individuals observe their own heat emissions through thermal imaging cameras. Each person radiates immense amounts of heat, a byproduct of metabolic processes. On average, the human body emits enough heat in an hour to light 19 matches. If utilized effectively, this emitted energy has the potential to contribute significantly to our energy needs.

Research efforts led by forward-thinking scientists are focusing on capturing this body heat to power wearable technologies—everything from smartwatches to health trackers. The vision is to create a device capable of operating similar to a power bank but integrated seamlessly into our clothing or accessories. This innovation could dramatically prolong the operational time of wearable devices and assist in the pursuit of a tech-savvy world where power sources can be generated naturally from the human body.

While harnessing personal heat is captivating, we must not overlook the vast amounts of waste heat produced by industries. Every day, heat generated from machinery and vehicle engines dissipates into the environment, representing a missed opportunity for energy recovery. The concept of waste heat recovery is gaining traction, as industries look to enhance operational efficiency and contribute to a greener planet.

Through efficient heat capture and conversion, industries can transform what was once considered excess into useable energy. Technologies that utilize the thermoelectric effect—the process of converting temperature differences into electric potential—are at the forefront of this revolution. Unfortunately, existing materials for such technologies often involve harmful substances like lead or mercury, which raise significant health and environmental challenges.

Research conducted at the University of Limerick, alongside collaboration with the University of Valencia, has unveiled a safer and more sustainable alternative to conventional thermoelectric materials: wood. Specifically, the study focuses on lignin, a byproduct of the paper industry. By exploring how lignin-based membranes can transform low-temperature waste heat into electricity, this research represents a paradigm shift in energy generation.

Lignin membranes, when treated with a salt solution, show impressive capabilities at converting waste heat (particularly below 200°C) into electricity. This energy conversion process leverages the movement of ions along the temperature gradient of the membrane, generating an electric potential difference. Given that approximately 66% of industrial waste heat falls within this optimal range, the implications of this technology are profound.

The ramifications of harnessing waste heat are substantial, especially for industries that consistently produce significant amounts of excess heat, such as manufacturing. By converting this waste into usable electricity, industries can enhance productivity while reducing their environmental impact. Furthermore, such innovations could be employed in diverse environments—from remote locations lacking conventional energy sources to everyday situations where powering devices seamlessly becomes routine.

The applications for this technology extend beyond mere energy production; they encompass sustainable living and advancements in energy conservation practices. By focusing on reimagining common materials as vital resources for renewable energy, this research redefines our understanding of everyday commodities in a sustainability-focused world.

While capturing energy from waste heat represents a crucial step toward sustainability, effective energy storage solutions are equally essential for practical applications. Supercapacitors, which allow for rapid energy charging and discharging, typically depend on carbon materials derived from fossil fuels—an unsustainable practice that must change.

Our research group is breaking new ground by exploring lignin-based porous carbon as an alternative for supercapacitor electrodes. This approach ensures that the energy harnessed through the lignin membranes can be stored effectively and environmentally responsibly. The integration of renewable materials into energy storage solutions paves the way for a self-sufficient energy-generating ecosystem.

The exploration of waste heat recovery is not merely an academic exercise; it represents a critical step toward sustainable energy practices that serve both our industries and individual consumers. Through innovative advancements, such as those involving lignin and other renewable materials, we have the opportunity to reshape how we harness and utilize energy, leading the way for a more sustainable and energy-efficient future.

Leave a Reply